|

Fuji Electric Co., Ltd. (headquartered in Tokyo, Japan; led by President Michihiro Kitazawa) is pleased to announce that today marked the first shipment of Exhaust Gas Cleaning Systems (EGCS) for ships from its Chiba Factory. 1. Background

In the aim of reducing emissions of sulfur oxide (SOx), a substance responsible for air pollution, the International Maritime Organization (IMO) has set an upper limit of 0.5% on the sulfur content of ship fuel oil in most sea areas※1 to be achieved by 2020 (current limit: 3.5%). This regulation will apply to all ships, existing and newly constructed ones. Once this regulation is strengthened, shipowners will have to address this by means such as switching to fuels with lower sulfur content or using SOx scrubbers. Fuji Electric has developed EGCS that is outfitted with a SOx scrubber that mixes exhaust gas with seawater and reduces the sulfur content of the gas. Today, the first shipment of this SOx scrubber left our Chiba Factory. ※1 Excluding the seas of North America and the Caribbean, the North Sea ,the Baltic Sea, and others. Regulated at 0.1% from 2015.

A FE SOx scrubber (Chiba Factory)

2. FE Product Features

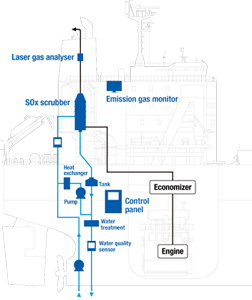

Our EGCS combines a SOx scrubber with a gas analyzer, which measures the concentration of substances in exhaust gas in real time, as well as inverters and controllers that control a feed water pump that takes in sea water. It boasts a SOx removal efficiency of over 98%, and can also be used in the sea areas regulated with a 0.1% sulfur limit.

・ Achieved the world’s smallest SOx scrubber thanks to our proprietary technologies SOx scrubbers made by FE are the first in the world to use cyclone technology in their internal structure. This technology can efficiently bring the seawater (or alkaline chemicals) and exhaust gas into contact by generating a vortex in the exhaust gas and spraying seawater from the pipes arranged spirally (as shown in the lower right figure). This is how we achieved the world’s smallest※2 SOx scrubber. It can be easily applied to existing ships with limited installation space, and the loss of loading space by mounting the system can also be reduced. ※2 About 50% smaller cubic volume compared with competitors’ existing products of the same engine output.

・Can be used in any sea area FE’s SOx scrubbers are available in both open loop and hybrid types. The open loop type is a system with a low investment burden, requiring few accessories, that uses seawater once and discharges it outside of the ship. The hybrid type combines open loop and closed loop technology (a method that uses circulating seawater with alkaline chemicals mixed in) so that ships can switch over in compliance with the regulations of the sea area in which they are operating. This makes it possible for the ship to operate anywhere, including sea areas where drainage is prohibited.※3 ※3 German rivers and ports, the three-mile Belgian coast and bays, and waters of the US states of California, Connecticut, and Hawaii ・Keeps operation costs down With this system installed, it is possible to continue to use current fuels (heavy fuel oil) instead of switching to low-sulfur fuels, thereby contributing to operation cost reduction for shipowners. We calculate that this system will yield a return on investment within about three years.※4 ※4 Calculated based on fuel consumption amounts for a 95,000 deadweight tonnage equivalent bulker using fuel prices as of September 2018.

FE-made SOx scrubbers using

3. Main applications Bulkers, tankers, containerships, car carriers, etc. 4. SOx scrubber specifications Each size is available in open loop and hybrid types.

5.Product Inquiries

Factory Automation Sales Engineering Department, Factory Automation Systems Division, Power Electronics Systems Business Group,Fuji Electric Co., Ltd. Telephone: +81-3-5435-7168 ※Information conveyed in this release (product features, prices, inquiry information, etc.) is accurate as of the date of this announcement and is subject to change without prior notice. |

Home > News & Events > Release of Power Supply Control ICs Offering Better Light-load Energy Efficiency

News Release

| October 11, 2018 |

| Fuji Electric Co., Ltd. |